Initial Understanding of TERZO: Answers About Lubricant Standards and Grades, and How TERZO Understands Lubricants

The suitability of a TERZO lubricant to provide a solution to a particular lubrication task must be clarified with the relevant machine manufacturers and plant manufacturers, as well as the technical lubricant services of mineral oil companies.

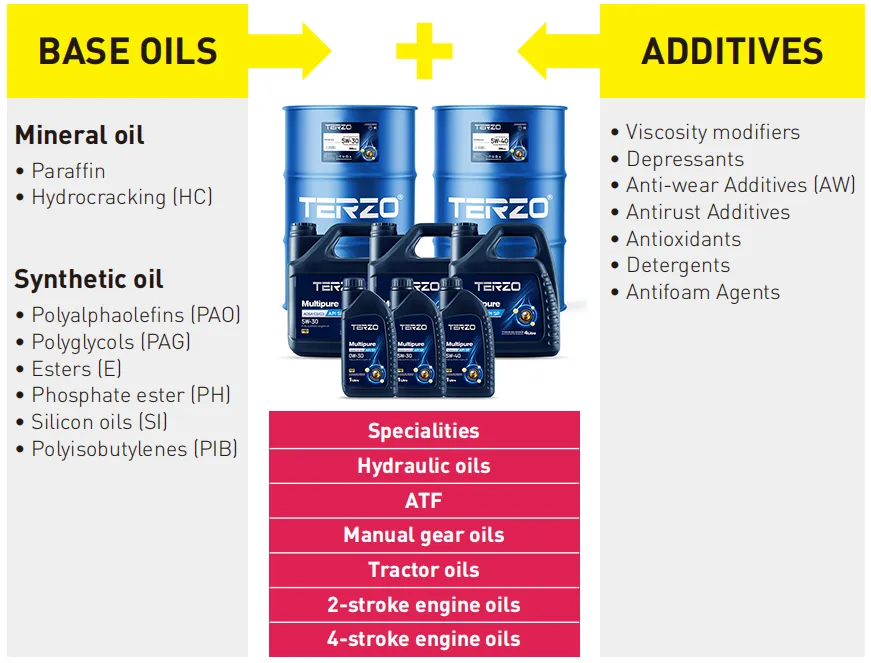

TERZO lubricants are synthesized from base oils and additives. Lubricants are used for lubrication purposes and serve to reduce friction and wear and tear as well as for power transmission, cooling, vibration damping, sealing effect and corrosion protection. A distinction is made between liquid lubricants (lubricating oils), pasty

lubricants (lubricating greases) and solid lubricants as well as gaseous lubricants (air).

| Synthetic oils | Miscibility with mineral oils |

|---|---|

| Polyalphaolefins (PAO) | excellent |

| Polyglycols (PAG) | bad |

| Ester oils (E) | good |

| Phosphate esters(PH) | bad |

| Silicon oils(Sl) | bad |

Among the common raw materials of lubricant, base oils include mineral oils such as paraffin and hydrocracking (HC); and synthetic oils such as polyalphaolefins (PAO), polyols (PAG), esters (E), phosphate esters (PH), silicone oils (SI), and polyisobutylene (PIB).

Additives include viscosity modifiers, pour point depressants, anti-wear additives (AW), anti-rust additives, antioxidants, detergents, and anti-foaming agents.

Through the action of base oils and additives, a series of automotive oils, hydraulic oils, automatic transmission fluids (ATF), manual transmission fluids, tractor oils, two-stroke engine oils, four-stroke engines, brake oils, gear oils, antifreeze and other products are generated.