O óleo para engrenagens de relação fixa em veículos elétricos apresenta um desafio aparentemente simples: um conjunto de engrenagens, malha constante, operando em uma enorme faixa de velocidade e carga. Obtenha o Óleo de engrenagem EV errado, e você compromete a eficiência, o ruído e a durabilidade.

Fórmula de nova geração aborda exatamente esses desafios, desenvolvido por meio da colaboração com fabricantes de veículos elétricos que enfrentam problemas de desempenho no mundo real com óleos convencionais adaptados.

Entendendo as demandas de transmissão de relação fixa

Ao contrário das caixas de câmbio ICE de várias velocidades, Redutores de velocidade única EV operam de zero a RPM máximo sem mudança de marcha. Isso cria padrões de estresse exclusivos para óleo para engrenagens de veículos elétricos. Em baixas velocidades com torque máximo durante a aceleração, predominam as condições de lubrificação de limite. Em velocidades de rodovia, o mesmo conjunto de engrenagens gira a 12.000-16.000 RPM, gerando calor intenso em uma carcaça compacta.

Tradicional óleos para engrenagens formulado para transmissões ICE:

Velocidades máximas mais baixas (normalmente abaixo de 6.000 RPM)

Períodos intermitentes de alta carga durante a troca de marchas

Temperaturas operacionais mais altas devido ao calor do motor

Redutores EV inverter essas suposições. Eles precisam Fluido EV propriedades que funcionam em faixas de velocidade mais amplas, mantendo temperaturas mais baixas em massa, mas lidando com pontos quentes localizados que podem ultrapassar 150°C nos contatos dos dentes da engrenagem.

Três pilares técnicos

- Os estoques de base sintética avançada formam a base. As misturas de PAO e ésteres proporcionam a fluidez em baixa temperatura essencial para a eficiência da partida a frio, mantendo a estabilidade da viscosidade em temperaturas elevadas. Não se trata apenas do índice de viscosidade, mas da estabilidade ao cisalhamento sob condições extremas na engrenagem dos dentes da engrenagem.

- A química proprietária dos aditivos equilibra as demandas concorrentes. Alcançando altos rigidez dielétrica (normalmente >35 kV) e, ao mesmo tempo, manter a proteção antidesgaste requer uma seleção cuidadosa de aditivos. Muitos aditivos tradicionais de extrema pressão contêm enxofre e fósforo ativos que funcionam muito bem para a proteção de engrenagens, mas criam problemas de condutividade elétrica.

- Fórmula do TERZO utiliza dispersantes sem cinzas e sistemas antidesgaste não condutores que protegem os enrolamentos de cobre e os ímãs de terras raras, além de evitar microfuros nas superfícies das engrenagens. Os testes mostram taxas de desgaste 40% mais baixas do que os fluidos ATF adaptados comumente usados nos primeiros modelos de EV.

- A estabilidade da oxidação térmica aumenta a vida útil. O Óleo para relação de marchas fixas TERZO Trans EV tem como meta intervalos de troca de 200.000 km em condições normais de operação. O teste de oxidação acelerada a 150°C mostra um aumento mínimo da viscosidade e do número de ácido ao longo de 1.000 horas, o que se traduz em desempenho mantido durante toda a vida operacional do veículo.

Trans EV: Especificações do produto

O Óleo para relação de marchas fixas TERZO Trans EV representa o compromisso da TERZO com lubrificação de veículos elétricos inovação:

Principais recursos de desempenho:

- Excelentes propriedades de isolamento impedindo o vazamento de corrente em Eixo eletrônico sistemas

- Recursos de resfriamento do acionamento elétrico gerenciamento de cargas térmicas de alta velocidade

- Controle de degradação térmica manutenção da estabilidade da viscosidade em serviço prolongado

- Formulação ecologicamente correta usando óleos básicos e aditivos não tóxicos

- Conformidade com REACH e RoHS da UE atender a rigorosas certificações ambientais

Especificações do aplicativo:

- Especificamente projetado para novas energias sistemas de acionamento elétrico

- Otimizado para transmissões de relação fixa e redutores de velocidade única

- Compatível com componentes de cobre e materiais de ímã de terras raras

- Adequado para passageiros EVsveículos utilitários esportivos elétricos e veículos comerciais elétricos

Desempenho real dos aplicativos

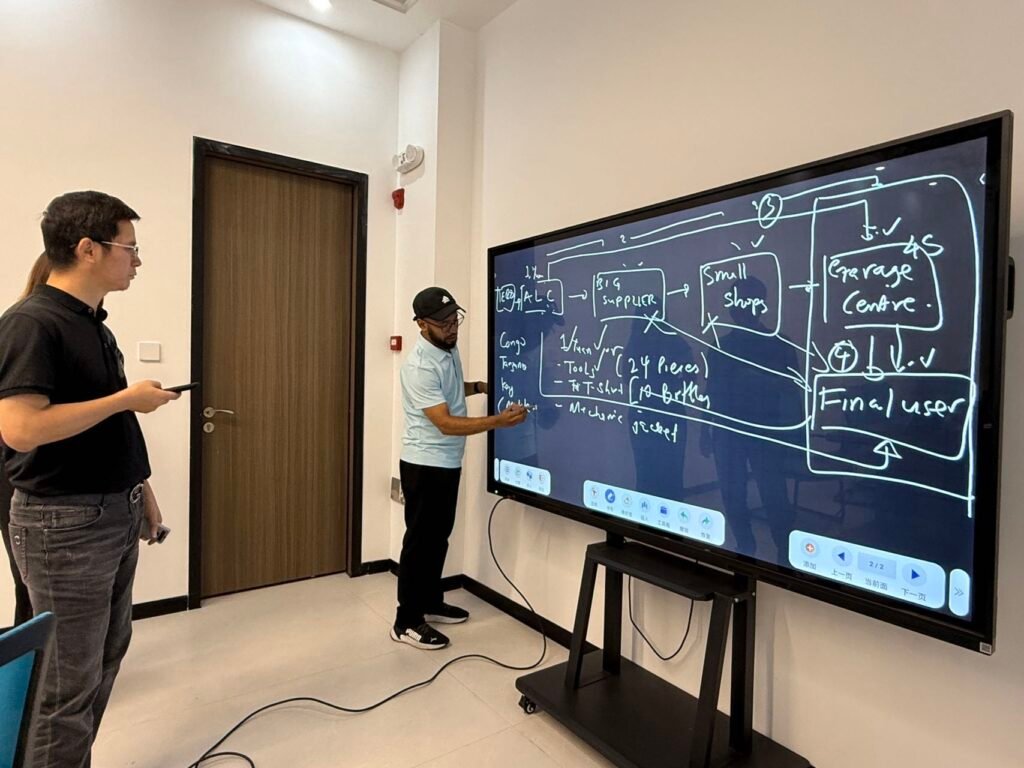

Trabalhar com um OEM europeu de médio porte durante sua Plataforma EV O desenvolvimento revelou pontos problemáticos específicos. Seus Fluido de transmissão EV A opção escolhida - um ATF sintético de baixa viscosidade - apresentou desempenho aceitável nos testes em clima quente, mas demonstrou três problemas na validação:

- Aumento do ruído em temperaturas frias devido à espessura insuficiente do filme

- Quebra de viscosidade após 100.000 km em veículos de alto uso

- Indicadores de corrosão em superfícies de rolamentos de cobre

Mudança para Óleo para engrenagens de relação fixa da TERZO durante os testes de pré-produção eliminou esses problemas. Os níveis de ruído diminuíram 3 dB em toda a faixa de temperatura, a análise de metais de desgaste mostrou uma redução de 60% no teor de cobre e a vida útil projetada foi ampliada para corresponder aos períodos de garantia do veículo.

Vantagens da cadeia de suprimentos

A capacidade de fabricação é cada vez mais importante à medida que as tensões comerciais afetam as cadeias de suprimentos automotivas. Instalações de produção da TERZO fornecer:

- Consistência entre lotes, atendendo aos padrões de qualidade automotiva

- Opções flexíveis de embalagem, desde IBCs a granel até garrafas prontas para o varejo

- Suporte técnico para conformidade com especificações e orientação de aplicativos

- Capacidade de ajuste rápido da formulação para atender aos requisitos específicos do cliente

- Certificações ISO/IATF/API que garantem o gerenciamento da qualidade

Para agentes regionais e parceiros de canal, isso se traduz em disponibilidade de estoque confiável e serviço técnico ágil - diferenciais essenciais ao competir por contratos de OEM.

Alinhamento ambiental e regulatório

Óleos para engrenagens EV enfrentam uma fiscalização regulatória em constante evolução. Fórmula do TERZO As características de biodegradabilidade excedem os requisitos atuais e antecipam os padrões futuros mais rigorosos. A formulação de baixa toxicidade reduz as preocupações com o manuseio e os requisitos de descarte.

Para as empresas de energia que estão diversificando a infraestrutura de VE, é necessário entender lubrificante para veículos elétricos Os impactos do ciclo de vida apóiam mensagens de sustentabilidade mais amplas. A formulação do TERZO permite uma comunicação transparente sobre o desempenho ambiental.

Por que escolher a TERZO

TERZO estabeleceu-se como uma empresa confiável Fabricante de óleo de engrenagem EV com recursos abrangentes:

- Experiência em P&D em lubrificação de veículos elétricos tecnologia

- Personalização OEM/ODM serviços para requisitos específicos de aplicativos

- Exportação por atacado recursos que atendem a mercados globais

- Certificações de qualidade (SGS, ISO, IATF, API), garantindo a confiabilidade do produto

- Presença regional nos mercados da Ásia-Pacífico, África, Ásia Central e Oriente Médio

Os distribuidores globais e agentes regionais se beneficiam do compromisso da TERZO com a inovação, a qualidade e a parceria com o cliente. Nosso rigoroso sistema de gestão da qualidade e nossa responsabilidade ambiental estão alinhados com os valores de uma empresa que pensa no futuro. EV fabricantes.

Óleo para engrenagens de relação fixa de nova geração da TERZO posiciona os parceiros para essa transição. Se você é um engenheiro de OEM especificando Fluidos EV para plataformas de última geração, um distribuidor que está criando portfólios de produtos ou um investidor que está avaliando as oportunidades da cadeia de suprimentos automotiva, é preciso entender o que é uma cadeia de suprimentos especializada. lubrificante para veículos elétricos torna-se cada vez mais essencial.

A tecnologia funciona. O mercado está crescendo. A pergunta para os possíveis parceiros: com que rapidez você pode integrar esse recurso à sua estratégia?

Saiba mais sobre a ampla gama de produtos da TERZO Analisador de óleo de engrenagem EV e como apoiamos Parceiros OEM em todo o mundo.