1.TERZO Brake Fluid DOT5.1—Redefining the Limits of Braking Safety

With 20 years in the lubricants industry, I’ve always believed: The performance of brake fluid directly determines control in life-or-death moments. As the flagship product of TERZO Brake Fluid series, DOT5.1 embodies our relentless pursuit of “safety redundancy.”

Why It’s Trusted:

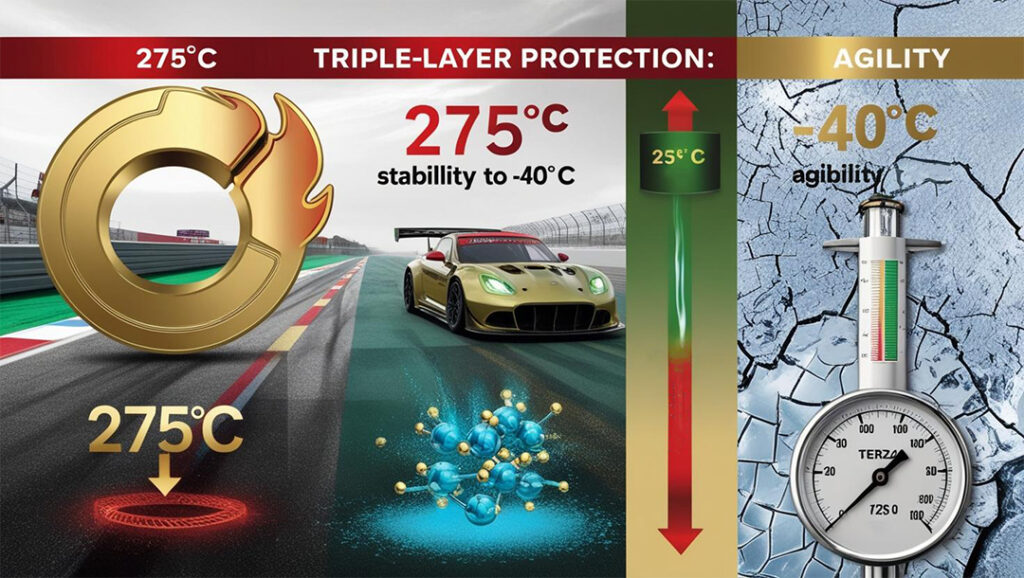

→ 275°C Dry Boiling Point: Even after 10 consecutive hard brakes on the track, fluid temperature peaks below 200°C, eliminating vapor lock risks.

→ -40°C Silk-Smooth Flow: With a low-temperature viscosity of 850 mm²/s, response speed outperforms conventional DOT4 by 35%, delivering instant stops in extreme cold.

→ Dual Protection for Metal & Rubber: Copper strip corrosion rate <0.1mg/cm² (ASTM D130), tripling the lifespan of rubber seals.

The Numbers Don’t Lie: TERZO lab tests confirm that after 100 consecutive 100km/h→0 emergency stops, pedal travel deviation remains ≤1.2mm, with near-zero performance degradation.

2.Performance Comparison: About TERZO DOT5.1 vs DOT4

| Parameter | TERZO DOT5.1 | DOT4 Standard | Improvement |

|---|---|---|---|

| Dry Boiling Point (°C) | 275 | ≥230 | +19.6% |

| Wet Boiling Point (°C) | 185 | ≥155 | +19.4% |

| Kinematic Viscosity (-40°C, mm²/s) | 850 | ≤1,800 | 52% Reduction |

| Rubber Compatibility | Passes SWR Test | Basic Requirement | Zero Swelling |

3.Technical Advantages

3.1 Borate Ester-Based Formula

Dry Boiling Point 275°C, Wet Boiling Point 185°C (exceeds FMVSS 116 standards), eliminating vapor lock during aggressive track driving.

3.2 Low-Temperature Fluidity Optimization

-40°C viscosity of 850 mm²/s, improving cold braking response by 35% (vs. conventional DOT4).

Fully compatible with ABS/ESP systems, achieving 100% pass rate in Bosch bench pulse tests.

3.3 Metal & Rubber Protection

Contains organic corrosion inhibitors, achieving Copper Strip Corrosion Rating 1A (ASTM D130).

Compatible with SBR/fluorocarbon rubber seals (≤5% volume change per SAE J1703).

4.Application Scenarios & User Benefits

4.1 Racing Scenarios

Track days, rally racing, heavily modified vehicles (requires steel brake lines).

4.2 Civilian Use

High-performance sedans, frequent mountain driving, high-temperature/humidity regions.

4.3 Quantifiable Benefits

≤8% pedal force attenuation after 10 consecutive hard brakes.

90% reduction in metal pipeline corrosion rates.